Foru's hydraulic cargo elevator, as an indispensable equipment in modern logistics and transportation, is crucial for the operational efficiency and safety of enterprises. It adopts a hydraulic transmission method, ensuring smooth operation with almost no vibration or impact during the lifting process. This not only guarantees the safety of cargo transportation but also reduces the risk of cargo damage.

The Working Principle of Hydraulic Cargo Elevators

The working principle of a hydraulic cargo elevator is based on the hydraulic system, providing stable and powerful lifting force through the combination of a hydraulic cylinder and a plunger. When hydraulic oil provided by the hydraulic pump enters the hydraulic cylinder, the piston of the hydraulic cylinder pushes the lifting platform upwards; when hydraulic oil flows out of the hydraulic cylinder, the lifting platform descends.

How to Choose a Suitable Hydraulic Cargo Elevator?

Determine Your Requirements

Lifting Height

According to your logistics needs and usage scenarios, determine the maximum required lifting height. Hydraulic cargo elevator can typically provide lifting heights ranging from several meters to over a dozen meters, ensuring the chosen elevator meets your specific requirements.

Load Capacity

Consider the weight range of the goods you usually need to transport and choose an elevator with a load capacity that meets your needs. The load capacity of freight elevators generally ranges from several hundred kilograms to several tons, so choose the appropriate specifications based on actual conditions.

Usage Frequency

If you frequently need to use the elevator for cargo transportation, it is very important to choose a durable model suitable for high-frequency use.

Consider Safety and Reliability

Safety Standards

Ensure the chosen elevator complies with local safety standards and regulatory requirements, such as CE certification.

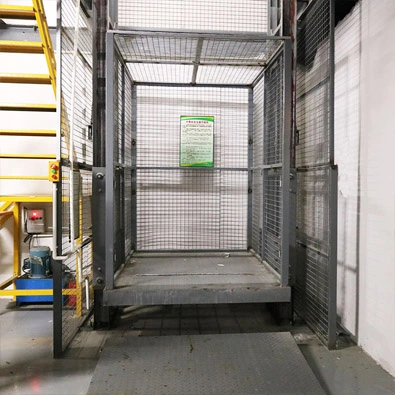

Protective Devices

The elevator should be equipped with comprehensive protective devices, such as guardrails and door lock systems, to ensure safety during operation.

Stability

Choose an elevator with a stable structure and excellent manufacturing quality to ensure smooth operation under various working conditions.

Consider the Ease of Operation and Maintenance

Ease of Operation

Choose an elevator that is simple to operate and easy to learn, lowering the threshold for employee use.

Ease of Maintenance

Elevator maintenance is crucial for the longevity and safety of the equipment. Choose a model that is easy to maintain and service, reducing repair costs and downtime.

Consider Space and Layout Requirements

Installation Space

Based on the layout of your logistics center or warehouse, choose a hydraulic cargo elevator with the appropriate size and installation method.

Layout Requirements

Consider the location and arrangement of the elevator's entry and exit points to ensure compatibility with existing logistics processes and spatial layout.