The vehicle rotating platform, as an important tool for vehicle display, maintenance and testing, is designed and manufactured with the wisdom and exquisite craftsmanship of engineers. This article will give you an in-depth look at how a vehicle rotating platform is designed and manufactured, from the design concept to the manufacturing process.

Design Concept: Function and Beauty Coexist

The first thing to consider in the design of vehicle rotating platform is its functionality. A good rotating platform needs to have smooth rotation performance, accurate positioning ability and sufficient load-bearing capacity. In addition, with the continuous development of the automotive industry, the vehicle rotating platform also needs to keep pace with The Times and adapt to the display needs of various new vehicles.

On the basis of functionality, beauty is also the goal pursued by designers. Modern vehicle rotation platforms not only meet the basic rotation and load-bearing needs, but also have an elegant appearance and smooth lines to enhance the overall effect of the car display.

Structural Design: Stability and Flexibility

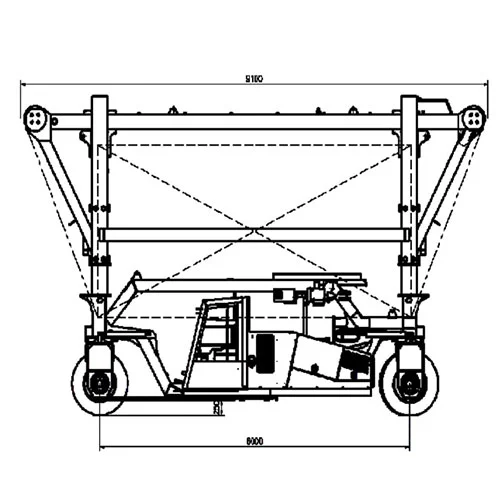

The structural design of vehicle rotating platform is a key step in the manufacturing process. Designers need to design a reasonable structural scheme according to the size, load-bearing capacity and use needs of the platform.

In structural design, stability and flexibility. Platforms need to use high-strength materials, such as high-quality steel or alloy materials, to ensure their load-bearing capacity and stability. At the same time, designers also need to consider the design of the platform's rotating mechanism, so that it can rotate smoothly and flexibly, and has precise positioning function.

Manufacturing Process: Fine Technology to Create High Quality

The manufacturing process of vehicle rotating platform includes material preparation, processing, assembly and commissioning.

First, the manufacturer will prepare the required materials according to the design scheme and carry out strict quality checks. Then, workers will use a variety of precision machining equipment to cut, drill, weld and other processing operations on the material to make the various components of the platform.

In the assembly process, workers will accurately assemble each part according to the design drawings, and make the necessary adjustments and calibration. Finally, after strict debugging and testing, to ensure that the platform has a good rotation performance and load-bearing capacity.

Quality Control and Continuous Improvement

Quality control is an important step in the manufacturing process of vehicle rotating platform. Manufacturers will develop strict quality control standards, and strict inspection and testing of each production link to ensure that the quality of the product meets the design requirements.

In addition, continuous improvement is also the goal pursued by manufacturers. They will constantly collect user feedback and market information, and continuously optimize and improve product design and manufacturing processes to enhance product performance and quality.

In short, the design and manufacture of vehicle rotating platform is a process integrating technology, art and wisdom. Through careful design, robust construction and sophisticated manufacturing processes, we are able to create high-quality, high-performance vehicle rotating platforms to support automotive demonstration, maintenance and testing.

Related topics recommendations:

Lightweight articulating boom lift

Electric hydraulic scissor lift

Narrow electric articulating boom lift

25m scissor lift

Vehicle mounted boom lift

Scissor lift maintenance

Articulating boom lift definition