Industrial lift for warehouse is a indispensable equipment in warehouse logistics. They are primarily used for the vertical transportation of goods, significantly improving warehouse operational efficiency. Industrial lift for warehouse utilizes hydraulic mechanical principles or electric mechanical principles to achieve the lifting and lowering of goods or personnel. According to their structure and working principles, they can be categorized into various types, such as guide rail lifts, scissor lifts, and hydraulic lift platforms.

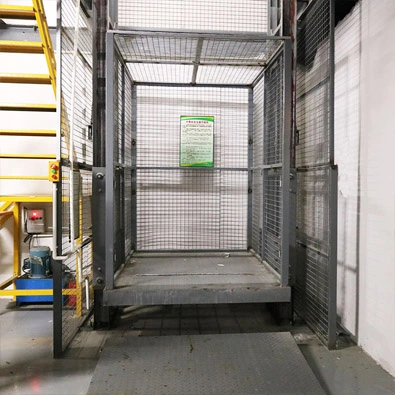

Foru's industrial lift for warehouse is designed to withstand the stringent demands of industrial environments, making them very suitable for transporting heavy goods between floors in warehouses, factories, and other industrial settings. Frequently used as construction lifts, they are meticulously designed, ensure safety, efficiency, durability, and feature smooth operation and long service life.

This article explains in detail the working principle and application scenarios of industrial warehouse freight elevators. Taking ForU brand products as an example, the details are as follows:

Main Features: Taking Foru's Industrial Lift for Warehouse as Example

Efficiency

Industrial cargo lift can quickly and accurately lift goods from the ground or lower positions to higher positions or lower goods from high positions to the ground, significantly enhancing warehouse operational efficiency.

Safety

Most industrial lifts are equipped with various safety protection devices, such as overload limiters and anti-fall devices, to ensure safety during the transportation process.

Stability

Utilizing advanced hydraulic or electric drive technology, the lifting process is stable and reliable, reducing the risk of damage to goods during transportation.

Flexibility

Industrial lifts can be customized according to the actual needs of the warehouse, such as lifting height and carrying capacity, to meet the usage requirements of different scenarios.

Working Principle of Industrial Lift for Warehouse

The working principle of industrial lift for warehouse is mainly based on the combination of vertical lifting equipment and horizontal conveyors. They use the up and down reciprocating motion of the lift platform to achieve vertical transportation of materials. Specifically, the lift platform is driven by hydraulic cylinders or electric motors to move vertically, thus completing the lifting and lowering of goods. Additionally, various types of conveying equipment, such as chains and belts, can be installed on the industrial hydraulic lift platform to coordinate with inlet and outlet conveying equipment, realizing fully automated flow of goods.

Application Scenarios for Foru's Industrial Lift for Warehouse

Industrial lift for warehouse is widely used in various warehouse logistics scenarios, such as:

Warehouse goods handling

Lifting goods from the ground or lower positions to high shelves or lowering goods from high positions to the ground for handling.

Production line material transportation

On production lines, transporting materials from one point to another, achieving automated production.

Inter-floor goods transportation

In multi-floor warehouses, transporting goods from one floor to another floor.